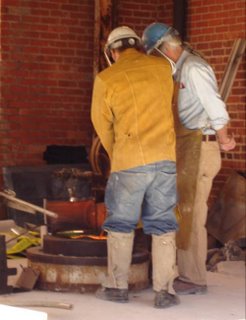

Also on Sunday, the sculpture dept. arranged a bronze pour to coincide with the end of the conference. The bronze program had just been started when I was still at Montevallo so I have done this. It is one of the few programs around that allow undergraduates to pour bronze. They also cast aluminum and have a killer welding and forging set-up. Any kind of metal work. I first learned to weld here when I took my first sculpture class. I believe in this photo they are lowering a bronze ingot into the crucible. That's the professor on the right. He is The Man. This guy knows how to do anything and is much loved by all the students, past and present.

Also on Sunday, the sculpture dept. arranged a bronze pour to coincide with the end of the conference. The bronze program had just been started when I was still at Montevallo so I have done this. It is one of the few programs around that allow undergraduates to pour bronze. They also cast aluminum and have a killer welding and forging set-up. Any kind of metal work. I first learned to weld here when I took my first sculpture class. I believe in this photo they are lowering a bronze ingot into the crucible. That's the professor on the right. He is The Man. This guy knows how to do anything and is much loved by all the students, past and present.

Here, they have picked the crucible up with the help of a little motorized chain hoist. The bronze is somewhere around 2,200 degrees F. I think. It is somewhere in that range. The crucible is made of silicon carbide, the same material that kiln shelves are made of. The little box looking things in front of them are the molds for what they are going to be pouring. There are several ways to make molds and different materials that can be used for the molds in casting bronze. These particular molds are resin-bonded sand and they are using the lost-wax method of casting which I think is fairly standard with bronze.

Here, they are pouring as you can see. It is a fairly nerve-wracking procedure; or it was to me. It can be very dangerous and you have to pay attention to everything. That is the prof. again there on the right. The students are actually doing everything themselves but he is guiding them along. That really helps the nervousness part.

Here, they are pouring as you can see. It is a fairly nerve-wracking procedure; or it was to me. It can be very dangerous and you have to pay attention to everything. That is the prof. again there on the right. The students are actually doing everything themselves but he is guiding them along. That really helps the nervousness part. They did not have to let the molds cool for very long at all (about 20 min.), so we were able to see them bust the pieces out. This mold actually cracked in the pouring but the piece was fine. I don't know if you can tell it is a hand. The forearm is still encased in the mold.

They did not have to let the molds cool for very long at all (about 20 min.), so we were able to see them bust the pieces out. This mold actually cracked in the pouring but the piece was fine. I don't know if you can tell it is a hand. The forearm is still encased in the mold.Edited to add: Kara, check my comments under the" Time Out" post and I tell all about how I got started in pottery etc.

4 comments:

Yep, bronze casting! A whole lot of fun. I've done this a couple of times at the local junior college, and I'm pleased with what I made. They don't offer the class now, but if they ever do again, I'll get back into it.

Yeah pablo, I really enjoyed it although the methods we used and the size of the castings we did at the time made it quite alot of work. I can certainly see why bronzes cost so much! But like you, I hope to do it again. You should show what you made on your blog!

http://www.roundrockjournal.com/?p=154

If this link works you can see one of the things I made in bronze. It's a bookend, of course, of the famous character Sisyphus.

I couldn't get the link to work and I tried to find it on your site just by searching but that didn't work either. :(

Post a Comment